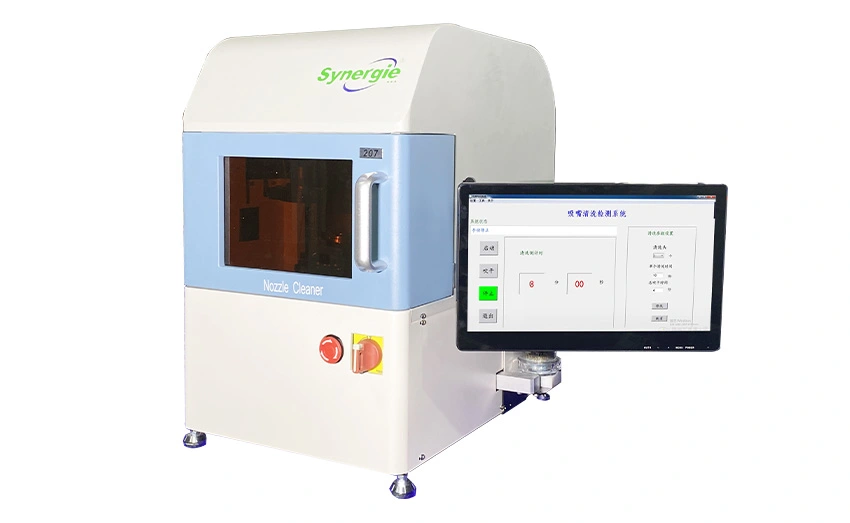

207 High-speed cleaning machine for suction nozzle

Detection, cleaning, dry and wet separation, the system operates independently

The cleaning process is controllable, and the unqualified products can be reflowed and re-washed

Quick wash, fine wash, single inspection, multiple mode selection. Just replace the tray and easily adapt to different suction nozzles

Key advantages

207The series of high-speed nozzle cleaning machines are the most cost-effective nozzle cleaning machines on the market developed by Synergie R&D engineers. Customers can obtain the cleaning effect of the smart nozzle machine at the price of an ordinary cleaning machine. The main advantages of this model are as follows:

- High speed cleaning: All suction nozzles on the market can be cleaned at high speed. The cleaning time of a single nozzle is as low as 3 seconds, and all kinds of stubborn stains in the nozzle can be removed.

- Quick air drying: Air drying mode program control, customers can set various air drying modes by themselves to remove the remaining water beads in the suction nozzle after cleaning.

- High cost performance: The system is controlled by an industrial computer program, and the installation location of the smart camera is reserved. Customers can expand the application by themselves, and are equipped with digital imaging and discrimination functions.

- High speed cleaning of suction nozzle: Quick cleaning is achieved through customized high-speed airflow and up and down reciprocating movements. After cleaning, the suction nozzle and suction nozzle plate are dried without water droplets

- Easy to operate: Industrial computer control, simple software operation, can check the nozzle detection status at all times, easy to use, safe to use.

Main Standers

- Effectively clean all kinds of stubborn stains - oil stains, dust, tin beads

- Effectively clean the inner wall of the suction nozzle, dirty, blocked, etc.

- Effectively clean the reflector

- Cleaning medium: deionized pure water

- Can MES connect

Extensible features:

- The vacuum degree detection of the nozzle can reach the accuracy ±100Pa

- QR code reading

- Smart camera imaging and recognition

Reduce material throwing and improve quality! Control the suction nozzle, Synergie is in action with you!

In a typical SMT In the patching process, the material thrown by the patching machine accounts for a considerable proportion of material loss. The material throwing of components is mainly affected by the following factors:

- Flaws in the components themselves

- Feeder fault

- Material packaging issues

- Throwing material during patch assembly

The main reasons are

- Inadequate adsorption force during adsorption

- Breaked nozzle, dirty and blocked inner holes

- Camera identification error (reflector damaged)

- Nozzle cushioning spring failure

- Nozzle type selection error (barcode type not recognized)

The above analysis shows that the material thrown by the patch machine accounts for a considerable proportion of material loss. In the reasons for material throwing, the defect of the suction nozzle accounts for a considerable proportion. The picture on the right is a certain SMT The chip production line, the material throw rate change trend chart after the introduction of the intelligent nozzle cleaning and testing machine. As can be seen from the figure, the nozzle after being controlled and maintained by the intelligent nozzle cleaning and detection machine can effectively reduce the material throw rate to 5% of ten thousand.

| Especificaciones | |

|---|---|

| Applicable models | Fuji NXT Series, Panasonic, Siemens, JUKI, YAMAHA All models |

| Subject sucking nozzle | H24/V12/H24G/XPF Wait for standard suction nozzle Siemens 933 /913/D Series and other standard suction nozzles Global 3420 /3430Wait for standard suction nozzle Panasonic 226 /110s/115s Wait for standard suction nozzle |

| External dimensions | 600X480X700mm |

| Weight | 45kg |

| Number of installations of nozzle plates | 1indivual |

| Maximum detection in a single cycle | 24indivual |

| Cleaning speed | Programmable customization, up to 360 seconds /24indivual |

| Cleaning tray | Different suction nozzle configurations are different (customizable) |

| Cleaning water | Pure water, tank capacity is 3 liters |

| Gas source | 0.5MPa |